flexiblediamondabrasive

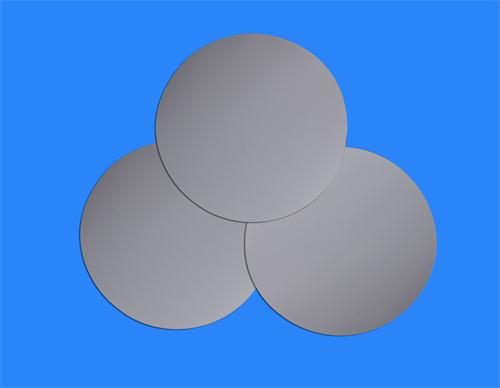

8" 10pcs Silicon Carbide Precision Lapping Films Disc

8" 10pcs Silicon Carbide Precision Lapping Films Disc

Cena regularna

$32.48 USD

Cena regularna

Cena promocyjna

$32.48 USD

Koszt wysyłki obliczony przy realizacji zakupu.

Ilość

Nie można załadować gotowości do odbioru

Engineered for precision grinding and edge retention, these lapping films combine a mylar film backing with resin-bonded abrasives for critical surface preparation.

Key Features

- Micron-Graded Abrasives: Premium silicon carbide or silicon dioxide particles (30–1µm) ensure precise, repeatable finishes.

- Durable Backing: Uniform thickness and planarity for consistent results on encapsulated or bare samples.

- Chemical Resistance: Withstands water, oil, and solvents for industrial workflows.

- Color-Coded Grits: Rapid identification of abrasive grades.

- Application Flexibility: Ideal for non-ferrous metals, polymers, and brittle substrates.

⚠️ Note: Not recommended for power head systems.

Material-Specific Recommendations

| Material | Recommended Abrasive | Key Applications |

|---|---|---|

| Non-Ferrous Metals | Silicon Carbide | Deburring, edge retention, and surface smoothing. |

| Polymers | Silicon Carbide | Minimizing heat-induced deformation during finishing. |

| Brittle Substrates | Silicon Dioxide | Low-aggression polishing for glass or ceramics. |

Usage Tips

- Surface Prep: Clean samples thoroughly to avoid embedding contaminants.

- Lubrication: Use coolants for heat-sensitive materials.

- Pressure Control: Adjust force based on hardness (e.g., soft polymers vs. hard metals).

Why Choose These Films?

- Edge Preservation: Critical for metallography and microelectronics.

- Cost Efficiency: Longer lifespan vs. traditional aluminum oxide abrasives.

- Customization: Available in tailored sizes or adhesives (e.g., PSA-backed).

Explore our lapping film range or contact us for specialized configurations.

Share