flexiblediamondabrasive

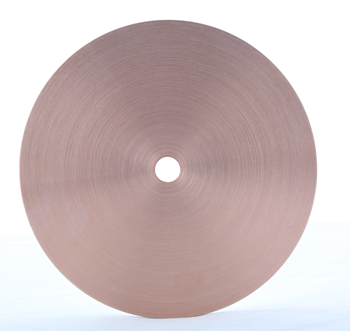

6"x1/2" Copper Flat Polishing Lap – 1mm Lapidary Glass Grinder for Stone, Glass & Gem Polishing

6"x1/2" Copper Flat Polishing Lap – 1mm Lapidary Glass Grinder for Stone, Glass & Gem Polishing

Nie można załadować gotowości do odbioru

Our Copper Flat Polishing Lap is a premium-quality lapidary tool designed for precision grinding, smoothing, and pre-polishing of hard materials such as gemstones, glass, and metals. Crafted from solid copper, this polishing Lap offers exceptional durability and efficient heat distribution, making it an essential tool for both professionals lapidarists and hobbyists.

Ideal for use with a flat Lap machines or faceting machine, this metal polishing wheel provides excellent support for diamond compound or loose abrasives, enabling smooth, uniform surface finishing. Its rigid construction ensures consistent contact and flatness, allowing for detailed, accurate work when shaping cabochons or faceting gems.

Whether you're performing coarse grinding or final polishing, the copper Lap excels in every stage. It’s especially effective as a glass polishing wheel or jewelry polishing wheel , and works well with rotary tools and other lapidary machines. If you're in need of a high-performance buffing polishing wheel that maintains its integrity over time, this copper Lap delivers.

Compatible with standard arbor sizes, it’s easy to mount and built to last through repeated, high-pressure use—making it a reliable choice for finishing sapphire, agate, quartz, or metal jewelry. Choose this high-gloss buffing wheel alternative for brilliant, professional results.

Share